Introduction to the paragraph

Choosing stone for decoration is really easy to step on pits!

All kinds of stone textures are advanced, and it is really expensive to install it! But in case of the wrong choice - serious chromatic aberration, inferior charging, and physical performance mismatch? It hurts money and sad every minute! Don't panic! As a senior stone man, Wayon Stone will come to share it today - a guide to stone procurement! Let you easily avoid all routines and choose satisfactory and good stone materials~

Ⅰ,Stone selection

Different areas of stone selection are affected by factors such as climatic conditions, architectural style preferences and use scenarios, and the demand for stone varieties varies significantly.

Choosing the right stone varieties can improve the beauty and practicality of the building and effectively control costs at the same time; conversely, it may cause a series of problems. Therefore, professional stone suppliers will "apply to the right medicine" and recommend really suitable stone materials and solutions for you.

01 Kitchen & bathroom space

Durable cleaning is rigid demand

Adaptation stone: Quartz, artificial stone

▶ Extremely dense: the water absorption rate is < 0.01%, soy sauce, water stains, etc. will be cleaned as soon as it is sprinkled, and penetration is eliminated from the root, and there is no pressure for daily cleaning.

▶ High hardness protection: Morse hardness reaches level 7, the tool scratches without leaving marks, can resist the impact of cooking utensils, and the surface is still flat for long-term use.

▶ Seamless stitching: The sink is integrated with the countertop to eliminate the dead corners of the gap, and the breeding of mold and dirt everywhere, and the maintenance is worry-free.

Special tips: Natural stone (marble, cave stone)

▶ Porosity is prone to seepage: the porosity of natural stone is high (for example, the porosity of cave stone is more than 10%), and there is a risk of infiltration of oil and water stains.

▶ Acidic and corrosive: vinegar, lemon juice and other acidic substances are easy to corrode the surface after contact, and need to be cleaned immediately, otherwise it is easy to cause traces of surface erosion.

What if Party A's father designates that the use of natural stone cannot be changed?

Don't be afraid! Professional stone suppliers will also provide corresponding solutions!

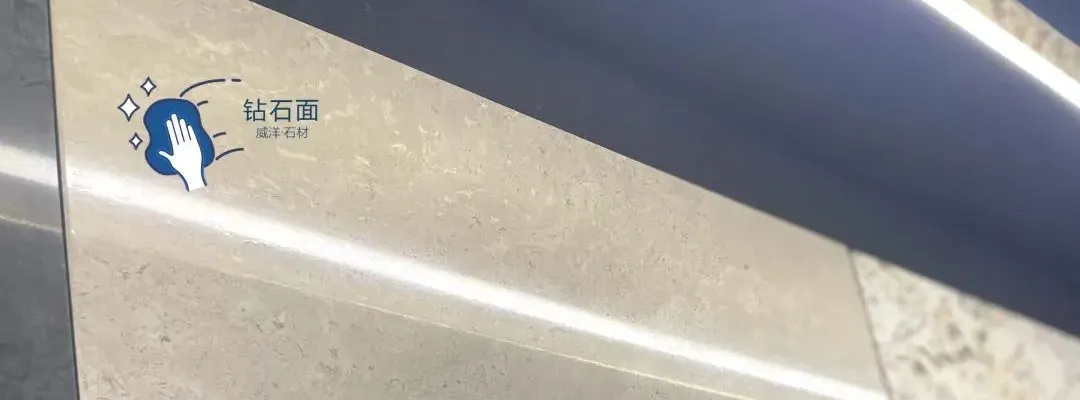

Like crystal surface treatment, a dense protective film is formed on the stone surface through special technology, which improves gloss and effectively blocks the penetration of oil and water stains;

Diamond surface technology strengthens hardness and wear resistance, and acidic splashes are also difficult to leave marks, which not only retains the unique texture of natural stone, but also solves practical pain points, making it both beautiful and durable.

02 Commercial space floor (hotel/market/office/apartment)

Wear resistance and pressure resistance are the key.

Suitable stone: High-performance artificial stone, brasive stone

▶ High-performance artificial stone: high hardness, tough surface, strong impact resistance, difficult to be scratched in daily use, stains are not easy to penetrate, and easy to clean.

▶ Grinding stone: excellent overall, seamless design to reduce dirt and scale, strong wear resistance, stable appearance after long-term use.

Special tips: Natural cavene and rock slabs (except thick rock slabs)

▶ The surface is easy to damage: long-term high-frequency trampling and heavy objects are dragged, and the surface of natural stone is prone to subtle scratches, which gradually loses its luster and affects the beauty of the space.

▶ Structure is easy to break: There are natural cracks inside the natural stone. When heavy objects (such as containers, equipment) are crushed, the cracks are easy to expand, resulting in stone fracture.

▶ High maintenance cost: regular maintenance is required, commercial operations are interrupted, and long-term investment is increased.

▶ Risk of use: The hardness of the slate is high, but the brittleness is larger than that of artificial stone, the repairability is insufficient, the fragments are sharp after fragmentation, and the safety factor is low.

03.Commercial space wall

The balance between texture and practicality

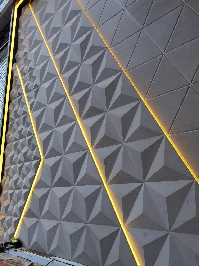

Adaptation stone: Ultra-thin soft stone, marble, high-performance artificial stone, gemstone, cave stone, cement stone

▶ Ultra-thin soft stone: lightweight and flexible, convenient construction and installation, retain natural texture, and can reduce building load.

▶ Marble: natural and unique texture, delicate texture, high decoration grade, natural environmental protection and a wide range of suitable scenarios.

▶ High-performance artificial stone: stain resistance and wear resistance, stable performance, controllable color without defects, environmental protection and radiation-free, excellent physical indicators.

▶ Gemstones: Rare and unique color and transparent characteristics can create a brilliant and luxurious visual effect.

▶ Cave stone: Natural holes give a simple texture, good breathability and good processing, which is suitable for creating artistic style space.

▶ Cement stone: low cost, strong plasticity, excellent durability and fire resistance, suitable for outdoor and large-scale application scenarios.

Special tips: Soft natural stones (such as partial marble), natural cultural stones

▶ Soft natural stone: poor wear resistance. After frequent flow of people, the surface is prone to scratches, wear and damage the beauty of the wall;

▶ Natural cultural stone: the weight of a single piece is large (5-10kg/m2), the exterior wall of the building is easy to fall off, and there are potential safety hazards; the concave and convex surface is easy to accumulate dust, moldy, and it is difficult to clean.

04 Furniture countertops

Zero penetration + corrosion resistance is the core

Adaptation stone: Quartz, high-quality marble, precious stones

Wayon Luxury Stone Seal

▶ Quartz: Mohs hardness level 6-7, excellent hardness and wear resistance, can withstand tool scratches and heavy object collision; the surface is extremely dense, the water absorption rate is almost zero, the stains are difficult to penetrate, and daily cleaning is easy;

▶ High-quality marble: the texture is diverse and natural, independent, the surface is hard, the impact resistance is strong, and it is not easy to scratch. The rich style and color can improve the beauty of the furniture.

▶ Gemstone countertop: It has both natural and unique color texture and excellent physical properties such as high hardness and strong corrosion resistance. Beauty and durability coexist.

▶ Wayon luxury stone imprint: choose natural jade stone, transparent and crystal, and cherish its unique natural texture. Apply innovative 3D printing solutions to realize ultra-high resolution reproduction of luxury stone images, flexible design and flexible performance, no distortion and no pixel flaws between millimeters.

Special tips: Natural porous stone

▶ Easy to seepage and discoloration: high porosity, dust, soot and liquids are easy to seep into the holes, forming dark spots and stains that are difficult to clean, affecting the beauty and hygiene of the countertop;

▶ Low hardness is easy to damage: Morse hardness is mostly at level 2-4. In daily use (such as tool scratching and heavy pressure), it is easy to scratches and dents, which quickly reduces the quality of the countertop.

The stone mentioned in the "Special Tips" does not mean that it is unusable. In fact, each kind of stone has its own unique aesthetic charm and suitable scenes. We are well aware that business decisions often take into account multiple factors such as design preferences, cost control and functional requirements.

Wayon Stone has always believed that there are no absolutely "wrong" materials, only unmatched solutions. We can provide a full set of solutions from stone selection, processing customization to installation and maintenance according to the functional needs of different scenarios and characteristics that are not suitable for stone, so that the most suitable stone can be selected in each scene, and the perfect combination of functions and aesthetics can be realized, so that project buyers do not have to worry about the details of material selection and easily solve the application problems of stone in each scene.

II. Supplier selection

Brand inspection

✅ Core focus

▶ Understand the reputation of the factory in the industry, and collect information through industry forums, customer evaluation and other channels. Check the age of the factory. Longer operating time usually means richer experience and more stable quality.

▶ Whether you have won an industry award is a strong endorsement of its products and services.

⚠️Risk Tips

▶ Choosing a factory with no brand or poor reputation may encounter problems such as unstable product quality and untimely service response, which will affect the overall quality and progress of the project.

▶ Newly established factories that lack market verification may have shortcomings in production process and management experience.

Scale investigation

✅ Core focus

▶ Production process and quality control: production process specifications (with clear process standards and connection mechanisms), equipped with a full-time quality control team (from waste to finished product quality inspection) to reduce cracks, chromatic aberration and other quality problems.

▶ Warehousing and logistics guarantee: have professional storage space (with moisture-proof and earthquake-proof facilities), cooperate with formal logistics (fixed and protective measures in transportation) to reduce the loss rate in storage and transportation.

⚠️Risk Tips

▶ If the factory is too small (small workshop-style factory), it may face the risk of insufficient waste material reserves, resulting in the outage of supply in the middle of the project, delaying the construction period and increasing the risk of default.

▶ The chaotic production process may lead to the loss of stone quality, cracks, chromatic aberration and other problems.

▶ The poor warehousing flow may lead to the moisture and damage of stone in storage and transportation, increasing the cost of loss.

Equipment inspection

✅ Core concerns

▶ Cutting equipment: five-axis linkage CNC cutting machine (accuracy ±0.5mm), supports high-precision machining.

▶ Polishing equipment: automatic polishing line (gloss 80-90GU, uniform consistency).

▶ Auxiliary equipment: edge grinding machine, chmfering machine (supports shape processing).

⚠️Risk Tips

▶ The lack of factory equipment and the lack of factory equipment of stone suppliers will directly lead to low production efficiency and difficult to guarantee the delivery date.

▶ Uneven polishing will cause the surface of the stone to be rough and prone to residual stains, and the difficulty of cleaning and maintenance in the later stage will be greatly increased.

▶ The lack of auxiliary equipment may lead to the inability to process special-shaped stone and meet the design needs of the project.

Certification inspection

✅ Scope of core certification

▶ Product safety certification (e.g. CE certification, national standard GB/T series): Ensure that the radioactive and physical properties of the stone (such as water absorption and strength) meet safety standards and adapt to indoor and outdoor scenes.

▶ Process control certification (e.g. ISO 9001 quality management system): Reflect the standardization ability from raw material procurement to quality inspection, and reduce the risk of quality problems such as chromatic aberration and size deviation.

⚠️Risk warning

▶ Stone without product safety certification may exceed the standard or be prone to rupture and staining.

▶ Factories without process control certification are prone to unstable quality and increase the cost of rework.

Price check

✅ Core concerns

▶ You get what you pay for: A reasonable price corresponds to the value of high-quality stone - it can ensure the use of standard raw materials, fine processing, compliance certification and perfect services, avoid quality hazards from the source, and ensure the long-term stability of the project (such as reducing later maintenance and avoiding rework).

⚠️Risk Tips

▶ Low-priced stone may use poor-quality raw materials (including cracks and impurities), simplifying the processing technology (omitting waterproofing and anti-fouling treatment), resulting in a shortening of the life of the stone by more than half, and cracking and seepage will occur 3-5 years after installation.

▶ Compliance testing may be omitted, poor-quality binders and dyes may be used to release formaldehyde, heavy metals and other harmful substances, especially indoor scenes will harm human health.

▶ The frequency of post-maintenance is far higher than expected (such as the need to be glued and polished every 3 months), and the total maintenance cost of 5 years may be higher than the "price difference" of the initial purchase.

Case investigation

✅ Core concerns

▶ Number of engineering cases: Prioritize suppliers with many years of industry experience and accumulated cases, paying special attention to the type of project that matches their own needs.

▶ Number and dimensions of photos: Each project needs to provide detailed drawings/process drawings (such as finished products in the workshop, packaging and delivery photos, construction site photos), focusing on checking the details of stone surface texture, stitching, corner processing, etc., whether they are consistent with the sample texture.

⚠️Risk Tips

▶ If there are very few cases in the supplier's factory (such as only 1-2 cases or most of them are small orders), there may be a problem of lack of industry experience. When facing complex orders (such as large-sized stone cutting, multi-category splicing), processing errors, delivery delays and other problems are likely to occur.

▶ There are very few photos of each project, only 1 - 2 long-term pictures, network pictures, or design drawings (not actual photos). There is a lack of details, and the difference in photo styles and light of different projects is too large. There may be a risk of stealing pictures and forgery, and the quality and technology of the actual delivered stone are seriously inconsistent with the case exhibition. .

Choosing a stone supplier is choosing a risk control partner! From brand qualifications, large-scale production capacity, equipment accuracy to certification cases, any omission may lead to quality loss, delay in construction, and even a safety crisis.

Wayon Stone has been deeply engaged in the stone industry at home and abroad for many years, providing risk prediction and response solutions for your project with mature processes, standardized processes and actual project accumulation, so that the stone can be traced from the mine to the site, helping to balance cost, delivery and quality, and reducing procurement risks.

Ⅲ.Service experience

Transportation and packaging

✅ Core focus

▶ Adaptability of packaging materials: whether to choose protective materials (such as thick solid wood frame + pearl cotton for large plates) according to the characteristics of stone materials to ensure impact resistance and extrusion resistance;

▶ Fixed process specification: whether the gap between the stone and the packaging frame is filled with cushioning materials (such as high-density sponges) to avoid shaking collision during transportation;

▶ Marking and handling guidelines: Are there clear reflective signs such as "fragile", "up" and "don't reverse" outside the package, with detailed handling instructions (such as the position of the forklift operation fulcrum);

⚠️Risk Tips

▶ Low-cost stone may use inferior waste materials (including cracks and impurities) for pressure prices, simplify the processing process (opt waterproof and anti-fouling treatment), resulting in a reduction of the life of the stone by more than half, and rupture and seepage 3-5 years after installation.

▶ Compliance testing may be omitted, using inferior adhesives and dyes to release harmful substances such as formaldehyde and heavy metals, especially indoor scenes, which can harm human health.

▶ The post-maintenance frequency is much higher than expected (such as glue and polishing every 3 months), and the total maintenance cost of 5 years may be higher than the "price difference" of the initial purchase.

Strong after-sales guarantee

✅ Core concerns

▶ The scope of warranty is clear: whether the warranty period is agreed in writing, covering the quality problems of the stone itself (such as cracking and aggravation of color difference caused by non-external forces) and installation-related problems (such as water seepage caused by poor stone protection).

▶ Response and resolution time limit: After receiving the after-sales demand, can you respond quickly and issue solutions (such as replenishment, maintenance)?

⚠️Risk Tips

▶ Suppliers without after-sales guarantee may shirk responsibility after a problem occurs (the goods turn over and do not recognize people when they go out).

▶ After-sales lack of response will lead to delays in project shutdown, surge in maintenance costs, mismatch of replenishment will affect the effect, and even bury safety hazards due to stone problems.

A little more caution when purchasing stone can save a lot of trouble - whether it is the detailed control when inspecting the supplier or the quality identification of the stone itself, it is not wrong to do your homework in advance.

If you think these dry goods are useful, don't forget to like + collect them. Next time you choose stone, turn them out and compare them. Don't take detours and don't step on pits! You are also welcome to forward it to friends who are decorating or purchasing stone, so that more people can avoid the "pits" of buying stone~