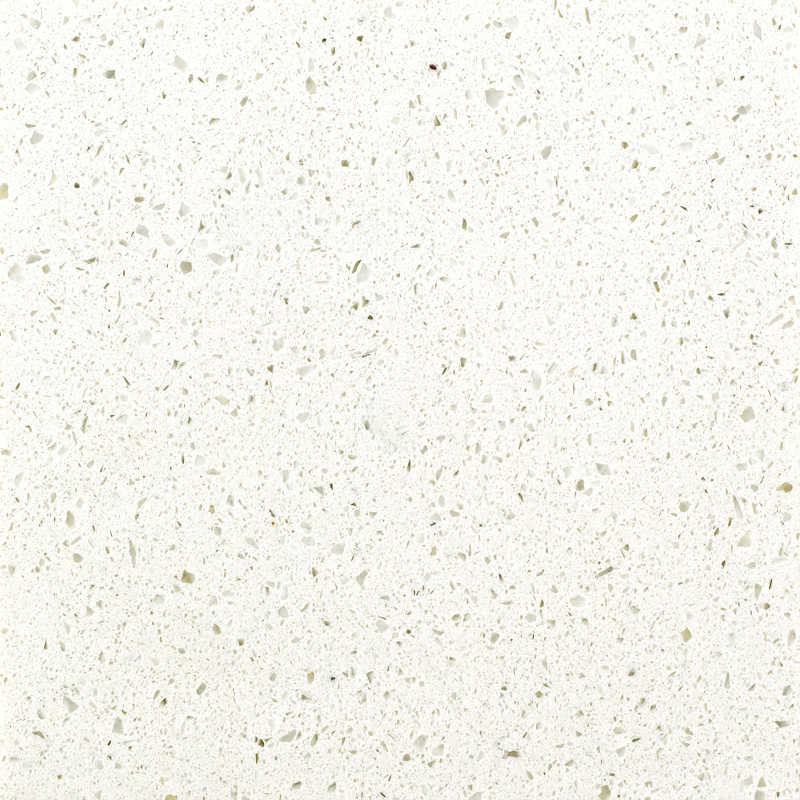

Quartz Slab Factory

Composition Of Top-Quality Quartz Stone

Resin is the matrix material of quartz stone, which plays the role of bonding and providing toughness to the quartz stone slabs. There are two main types of resins used in quartz stone: one is unsaturated polyester resin and the other is acrylic resin.

1.Filler

The main component of the quartz stone filler is silica. As a fire retardant, it can fill the volume and enhance the stone texture and mechanical properties.

2.Pigment

Mainly used to deploy color varieties to make the quartz stone colorful. In theory, any color can be deployed through various types of pigments.

3.Quality Resin

As a binding agent, resin holds the crushed quartz particles together to cure under high heat and pressure, creating a solid and cohesive quartz stone surface.

4.Unique auxiliaries

appropriate addition of auxiliaries can improve the process performance of resin to promote production efficiency and extend the lifespan of the quartz stone.

Professional Countertop Factory – WAYON

WAYON is one of the largest quartz stone manufacturers in China in terms of production scale. Our products are exported to Europe, America, Australia, Africa, and Asia. From the first step of raw material selection, we insist on selecting high-quality quartz sand and resin. Through advanced technology and equipment, the whole production process is far lower than the traditional stone in terms of dust, wastewater and carbon emission, which is perfectly in line with the 3Rs - Reduce, Reuse and Recycle.

WAYON quartz stone quality is recognized by the U.S. NSF National Science Foundation, Greenguard Gold, Greenguard Indoor Air Quality Certification, SGS certificate and BV Certification and other authorities, which are the high standard of verifications of imported stone in Europe, America, Australia, Africa, and Asia. As a professional countertop factory with more than 40 years of experience, we insist on supplying our customers with high-performance first-class quartz stone table tops.

Quartz Slab Manufacturers

Explore more creative options for your countertop!

The current development direction of quartz stone products is mainly in kitchen countertops, bathroom countertops, bars, coffee tables, floors, and internal and external wall headers. They have become the perfect alternative to natural stone, high-grade ceramics, wood, metal, and other decorative materials.

Frequently Asked Question

Do you have any question?

Quartz stone has a relatively large price range - the simple pattern is less expensive than gorgeous and complex ones to suit different needs. And no matter how the color or price, it is better than granite in terms of performance.

Quartz is actually harder and more durable than granite. Quartz is virtually indestructible and not as porous as granite, keeping your countertops relatively bacteria-free.

Quartz stone has excellent acid and alkali resistance. It is easy to clean and take care of and has no crevices where bacteria can hide, making it very suitable for hospital countertops, laboratory countertops, etc.

Our updates and blog posts

Is the kitchen decorated too ordinary? Have you chosen the right panel

Kitchen | a space to satisfy taste buds and soul The kitchen stores the taste of the family. In this era when takeout is more convenient and fast, we can enjoy life only when we know how to eat bread, rice and salt.

Don't know how to choose quartz stone countertop?

Dry goods sharing About Quartz Stone Origin of quartz In 1984, quartz stone was developed by the "Stone Kingdom - Italy" Bridgetown Company. Later, this new type of artificial stone.

Wayon quartz raw materials better! More! Near!-(quartz stone)

As well-known, high-quality quartz surface is made of quartz stone, proportion up to about 93% Manufactured in the vacuum and high pressure environment.