TERRAZZO Tile MANUFACTURER

terrazzo Woes No More: Tackling Common Issues in terrazzo Slab Care

WAYON has been at the forefront of the terrazzo trend, with a focus on research and development. As the global retro terrazzo wind back to the present, we proudly launched the high-quality, high-performance, and eco-friendly inorganic terrazzo series. They fully comply with the standards of inorganic terrazzo and outperform most others available in the market.

Strength

High compressive strength (90-123MPa), and high flexural strength (9.8-13.5MPa), so that the WAYON inorganic terrazzo is almost unbreakable whether it is lifting, cutting, or polishing. It is also capable of various processing techniques.

Performance

Composed of inorganic materials, WAYON inorganic terrazzo is highly fire-resistant and non-combustible. With a lower-than-average water absorption rate (0.19-0.53%), it is perfect for interior walls, flooring, kitchen and bathroom countertops, and other areas.

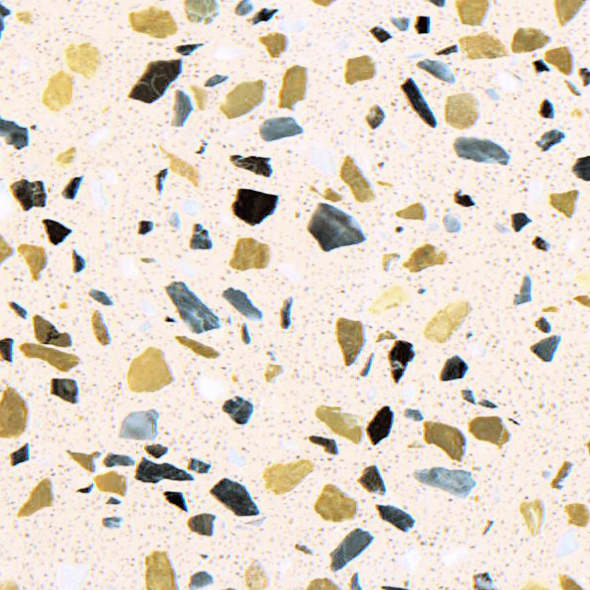

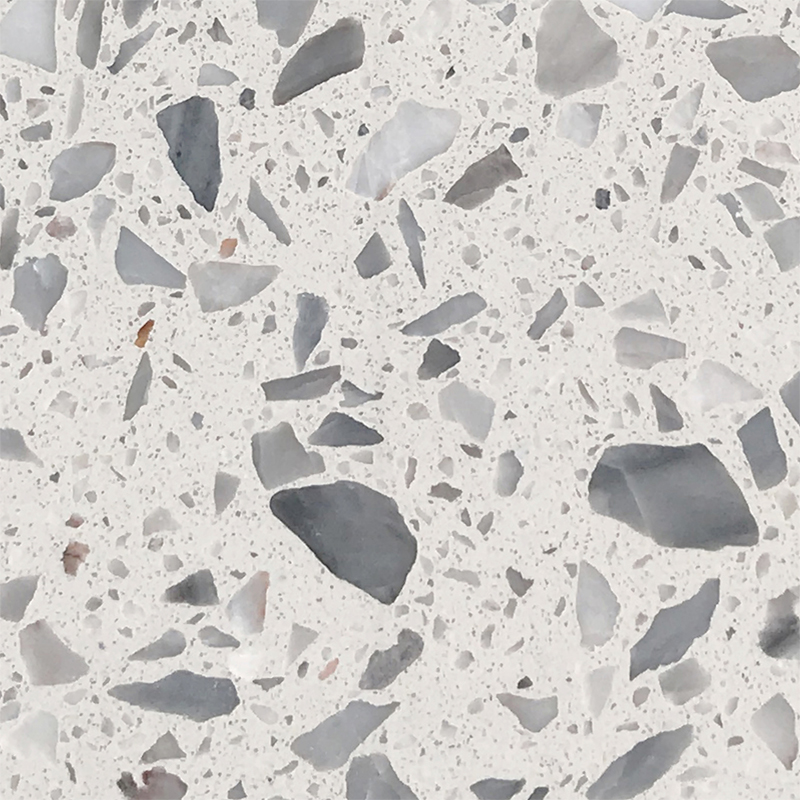

Appearance

Adopting high-quality raw materials and advanced production technology, our inorganic terrazzo has a smooth and glossy surface, even without any surface treatment, which is an excellent choice that will exceed your expectations.

Durability

WAYON inorganic terrazzo has excellent abrasion resistance, high hardness (Mohs Hardness Scale up to 4-6 degrees), and high density (2.44-2.53g/cm³), which is superior to most of those from other brands on the market.

Reshaping Modern Spaces with Timeless Charm With WAYON

We source natural marble particles and quartz sand from our own mines and adopt a self-developed inorganic mix and imported concrete to produce stable, dense, and high-performance terrazzo. Our inorganic terrazzo is then surface-ground and polished to create a colorful and unique style of terrazzo, and irregular stone patterns deliver a random and natural beauty. Also, we offer a variety of processes to enhance the appearance and durability of our terrazzo, making them an ideal decoration for any contemporary space.

45° Splicing: The edges of the two pieces of terrazzo are cut at a 45-degree angle and then spliced together to form a diagonal seam. This helps to create a smooth transition between the two pieces of terrazzo, reducing the visibility of the seam to improve aesthetic appeal.

Litchi Surface Treatment: It is similar to the rough and concave skin of a lychee fruit, which is the processing that most test the compressive and flexural strength of the stone materials.

- Add beauty to the treated surface. Textured finishes create visual interest and can be used to enhance the overall design of a space.

- Withstand heavy foot traffic or vehicle loads without noticeable wear or deterioration, making it a popular choice for high-traffic areas.

- Improve the slip resistance of terrazzo with better traction and grip, reducing the likelihood of accidents or falls. It is especially suitable for use in areas with a risk of slipping, such as outdoor sidewalks, ramps, or wet areas.

Flamed Finishing Process: It is the process that most tests the fire resistance of the stone slabs. The intense heat causes the crystals in the terrazzo to expand and break apart, creating a rough and uneven texture. Then it cools rapidly, further enhancing the texture and durability of the surface.

On the one hand, the flamed finish adds a unique aesthetic to the terrazzo. The rough and textured appearance creates a natural rustic look that complements a variety of architectural styles and design themes. On the other hand, it improves the stone's resistance to weathering and external factors, making the surface more resistant to fading, moisture absorption, and chemical damage, thus increasing the durability and longevity of the stone.

TERRAZZO TILE FACTORY

WAYON Terrazzo: Harmonizing Patterns and Elegance

In today's world, people are searching for cozy and luxurious living spaces, expecting top-notch quality in their home decor materials. With its versatility and aesthetic appeal, terrazzo has become the go-to choice for designers. WAYON terrazzo finds its application in a broad scope of areas worldwide, such as commercial spaces, homes, outdoor flooring, furniture, bathroom sinks, and ornament.

CHINA TERRAZZO TILE

FAQs

Inorganic terrazzo is made of stable and non-combustible inorganic substances, making it chemical resistant, freeze-thaw resistant, non-combustible, and can be used in outdoor building materials.

WAYON precast inorganic terrazzo is molded by high-frequency and high-pressure vibration pressing, which embodies - high flexural strength, high compressive strength, high density, low water absorption, and other properties in terms of performance.

As it is a one-piece molded product of the production line, it is more uniform and beautiful in pattern fabric, and each piece of terrazzo has high overall similarity and less deviation.

Our updates and blog posts

Is the kitchen decorated too ordinary? Have you chosen the right panel

Kitchen | a space to satisfy taste buds and soul The kitchen stores the taste of the family. In this era when takeout is more convenient and fast, we can enjoy life only when we know how to eat bread, rice and salt.

Don't know how to choose quartz stone countertop?

Dry goods sharing About Quartz Stone Origin of quartz In 1984, quartz stone was developed by the "Stone Kingdom - Italy" Bridgetown Company. Later, this new type of artificial stone.

Wayon quartz raw materials better! More! Near!-(quartz stone)

As well-known, high-quality quartz surface is made of quartz stone, proportion up to about 93% Manufactured in the vacuum and high pressure environment.